Why Fluid Health 360° ?

CNC shops have some key focus areas to maximize productivity and minimize costs on the shop floor. These include

INCREASING TOOL LIFE

REDUCING THE RISK OF MARRING AND REWORK

REDUCING THE RISK OF UNPLANNED DOWNTIME

EXTENDING FLUID LIFE

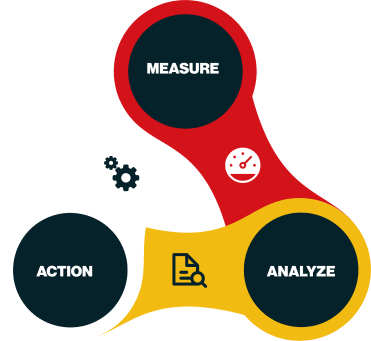

Recording simple fluid health measures and analyzing the data to provide alerts and insights for proactive action will help in achieving these key objectives.

What are the health checks your shop floor operators should run?

When should they run them?

Where should they record the results?

How can supervisors and managers be alerted to machines that require their attention?

FluidHealth360° answers these questions and many more.

Fluid Health 360° Vision

To make the checking and replacement of fluids based on data and automation, thereby cutting costs, ensuring consistent performance and avoiding unexpected breakdown

The Fluid Health 360° Solution offers

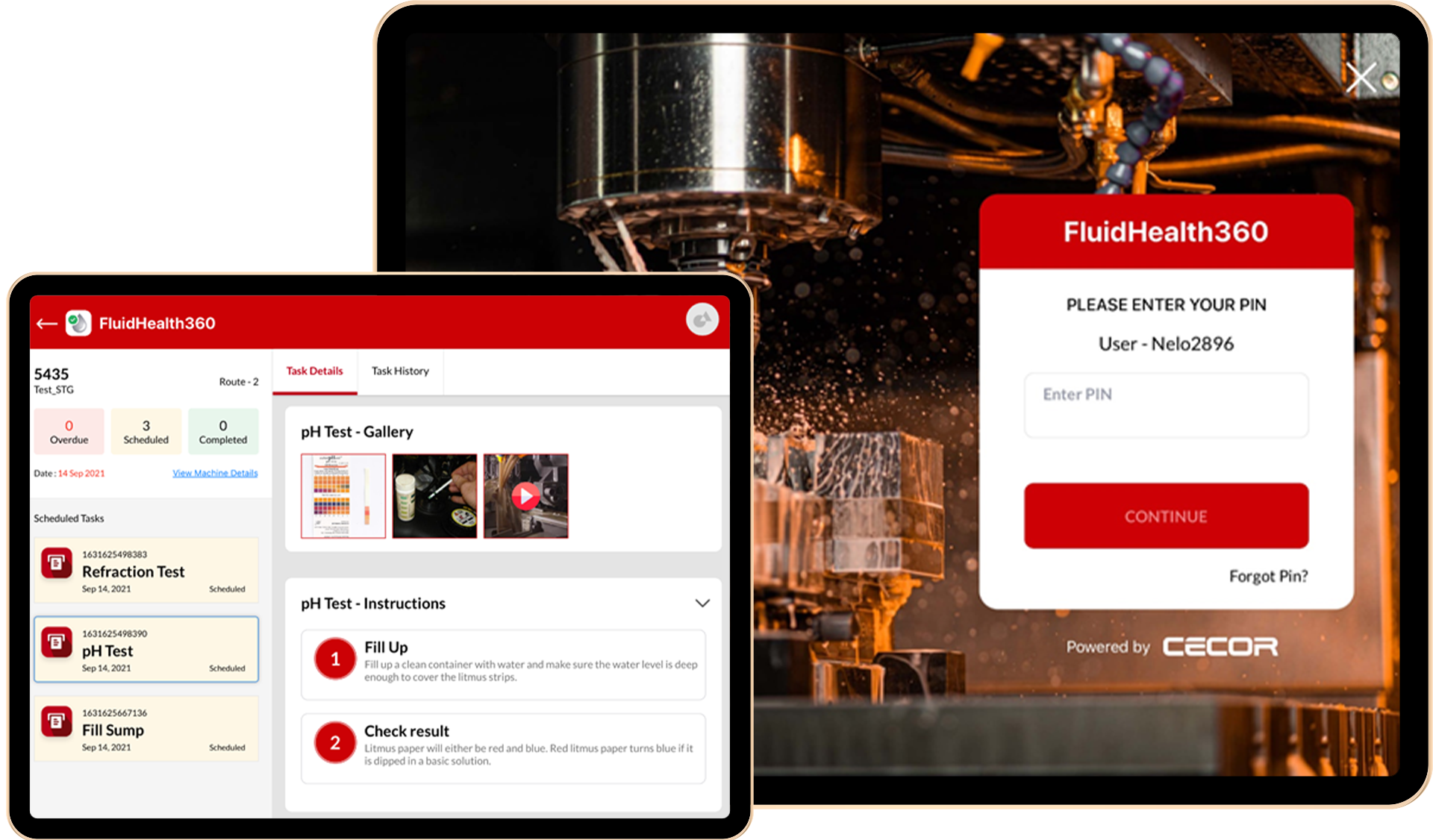

Smart I-Pad App

for operators

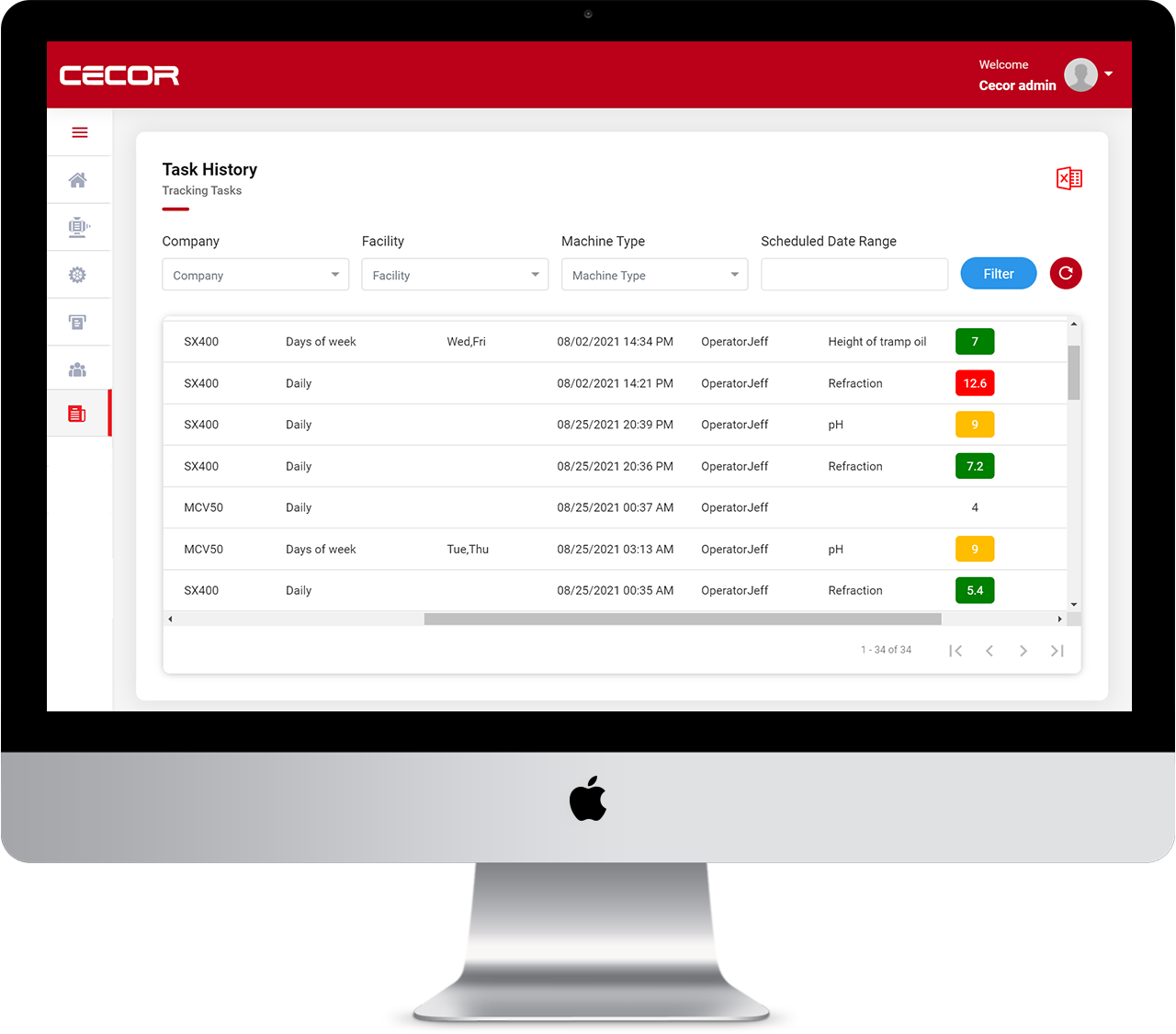

Web App

for Administrators

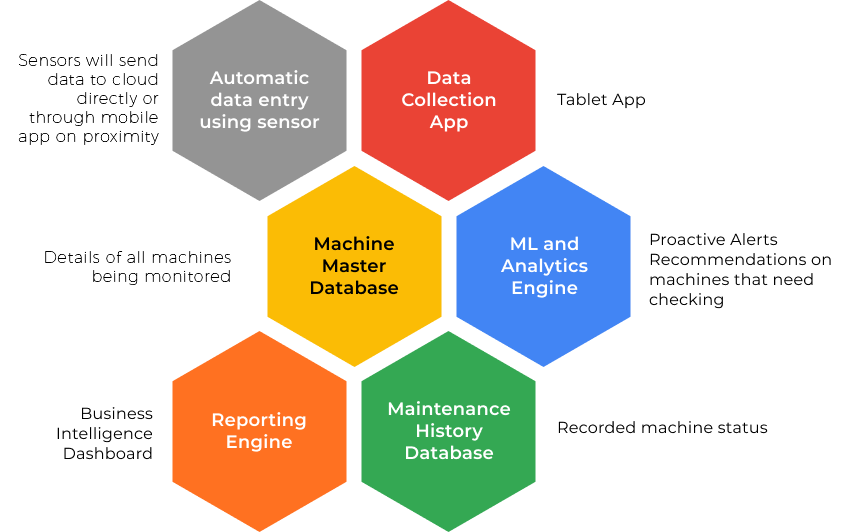

How it works

Ipad App for operators

Actionable Insights for Management

WHAT INFORMATION CAN YOU GET FROM RECORDED DATA?

- Information on fluid health

- Level of tramp oil in each machine

- How tramp oil removal devices are working on each machine

- Sludge level in each sump

- Information needed by fluid reps for analysis

WHAT ANALYTICAL INSIGHT CAN YOU GET FROM THE RECORDED DATA?

- Machines that need attention

- Trends of vital fluid measures over time

- Environmental influences on your metalworking fluid

- How to extend fluid life

- Predictive reporting to eliminate potential product problems and unexpected shutdowns due to poorly maintained metalworking fluid.